- Media library

DCAM media library

DCAMCUT premium EDM Software for 30 Years

-

# 008 DCAMCUT 8.5 multi-axis machining simultaneously. You can use this DCAMCUT module to program component geometries that would not be editable without additional axes. Maximum machine autonomy, even largest conics, with maximum accuracy and surface quality.

# 008 DCAMCUT 8.5 multi-axis machining simultaneously. You can use this DCAMCUT module to program component geometries that would not be editable without additional axes. Maximum machine autonomy, even largest conics, with maximum accuracy and surface quality. -

# 007 DCAMCUT 8 5 with a new look and bundles

# 007 DCAMCUT 8 5 with a new look and bundles -

# 006 efficient reduction of changeover times through indexed multi-axis machining: With the option of indexed multi-axis machining, changeover times of components with multiple clamping can be reduced by a considerable degree. In addition, errors in aligning and probing of the individual processes are avoided. Sources of error are minimized and productivity increased.

# 006 efficient reduction of changeover times through indexed multi-axis machining: With the option of indexed multi-axis machining, changeover times of components with multiple clamping can be reduced by a considerable degree. In addition, errors in aligning and probing of the individual processes are avoided. Sources of error are minimized and productivity increased. -

# 005 more autonomous machine running time through intelligent clearing strategies, part 2: In the second part of the webinar for our intelligent clearing strategies, we specifically focus on the functions in the 4-axis area. Here, different partial contours are removed with a conic, for example, to remedy the problem of removing the defective part.

# 005 more autonomous machine running time through intelligent clearing strategies, part 2: In the second part of the webinar for our intelligent clearing strategies, we specifically focus on the functions in the 4-axis area. Here, different partial contours are removed with a conic, for example, to remedy the problem of removing the defective part. -

# 004 more autonomous machine runtime through intelligent clearing strategies, part 1: In this webinar, we will show you our different clearing strategies with which you can optimally use the machine running times.

# 004 more autonomous machine runtime through intelligent clearing strategies, part 1: In this webinar, we will show you our different clearing strategies with which you can optimally use the machine running times. -

# 003 intelligent template technology in DCAMCUT: Here, we discuss possible scenarios and problems that have to be solved with the template technologies in DCAMCUT and that lead to a program for your machine even faster. From simple drill hole templates and color recognition features to complex and nested program templates, we show you how to create and use the template technologies and their advantages compared to a step-by-step approach.

# 003 intelligent template technology in DCAMCUT: Here, we discuss possible scenarios and problems that have to be solved with the template technologies in DCAMCUT and that lead to a program for your machine even faster. From simple drill hole templates and color recognition features to complex and nested program templates, we show you how to create and use the template technologies and their advantages compared to a step-by-step approach. -

#002 helpful CAD functions for contour generation: Here, we present the most important functions from the CAD area, through which contours and CAD models can be prepared or adapted. This step may be necessary if external data has to be processed or processing requires an adjustment of geometry traces.

#002 helpful CAD functions for contour generation: Here, we present the most important functions from the CAD area, through which contours and CAD models can be prepared or adapted. This step may be necessary if external data has to be processed or processing requires an adjustment of geometry traces. -

#001 3D contour generation with DCAMCUT simple and fast: Here, we present the most important functions from the CAD area, through which contours and CAD models can be prepared or adapted. This step may be necessary if external data has to be processed or processing requires an adjustment of geometry traces.

#001 3D contour generation with DCAMCUT simple and fast: Here, we present the most important functions from the CAD area, through which contours and CAD models can be prepared or adapted. This step may be necessary if external data has to be processed or processing requires an adjustment of geometry traces. -

DCAMCUT machine setup made easy

DCAMCUT machine setup made easy -

DCAMCUT service set

DCAMCUT service set -

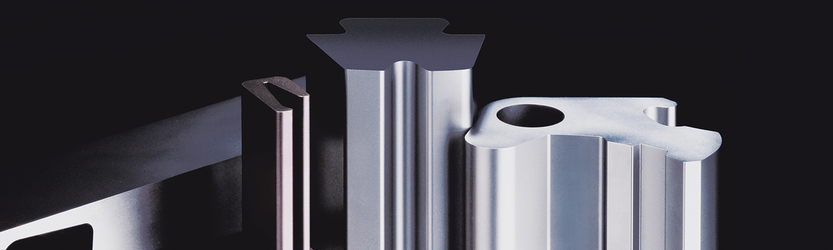

DCAMCUT - contour definition directly on 3D surfaces: DCAMCUT is a comprehensive CAD/CAM software solution for wire erosion in tool or mold making, automotive and mechanical engineering.

DCAMCUT - contour definition directly on 3D surfaces: DCAMCUT is a comprehensive CAD/CAM software solution for wire erosion in tool or mold making, automotive and mechanical engineering. -

DCAMCUT wizard: The wizard is a tool that guides the operator through programming in DCAMCUT. It virtually takes the operator by the hand and explains all the steps necessary for a successful program output for wire cutting.

DCAMCUT wizard: The wizard is a tool that guides the operator through programming in DCAMCUT. It virtually takes the operator by the hand and explains all the steps necessary for a successful program output for wire cutting. -

Performance overview DCAMCUT: This video provides an overview of various DCAMCUT features, including 4-axis clearing, turning and swiveling operations, and simultaneous machining and erosive grinding.

Performance overview DCAMCUT: This video provides an overview of various DCAMCUT features, including 4-axis clearing, turning and swiveling operations, and simultaneous machining and erosive grinding. -

NC browser: Our NC browser provides all the relevant information for the user in order to check the wire EDM program created. In addition, it offers the option of visually displaying the NC code for the user.

NC browser: Our NC browser provides all the relevant information for the user in order to check the wire EDM program created. In addition, it offers the option of visually displaying the NC code for the user.