Release Note 9.0.21746

03/16/2024 Release DCAMCUT 9.0.21746

Added

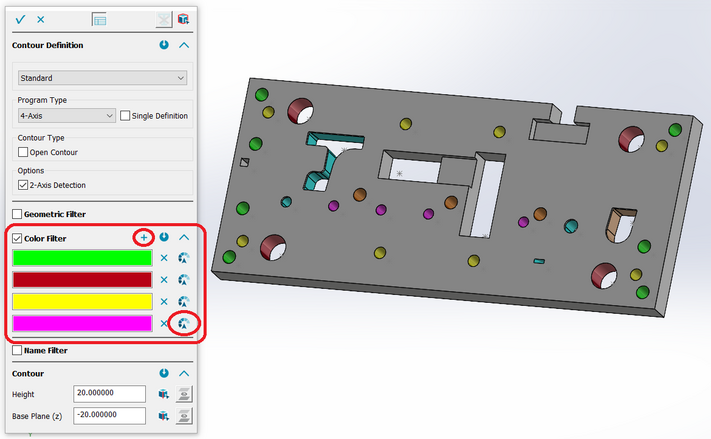

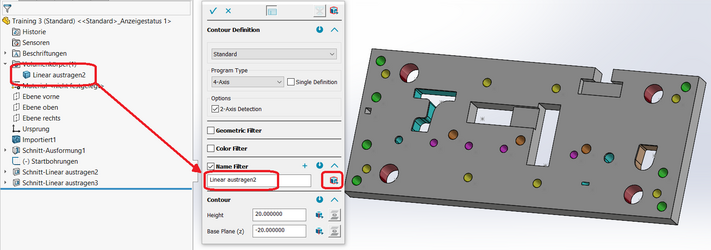

> New options for generating contours

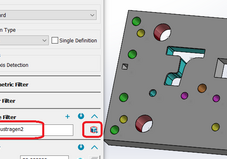

- Name filter to create contours

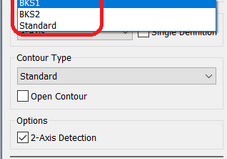

- Contour creation with multiple colors

> New selection filters

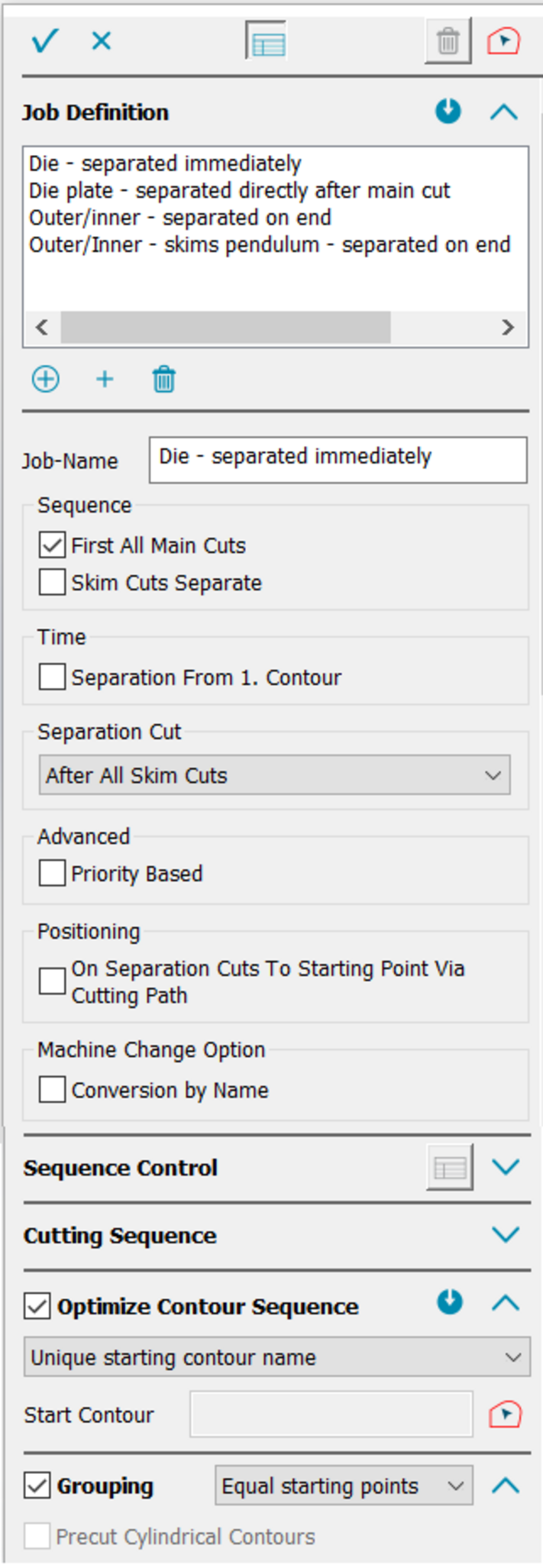

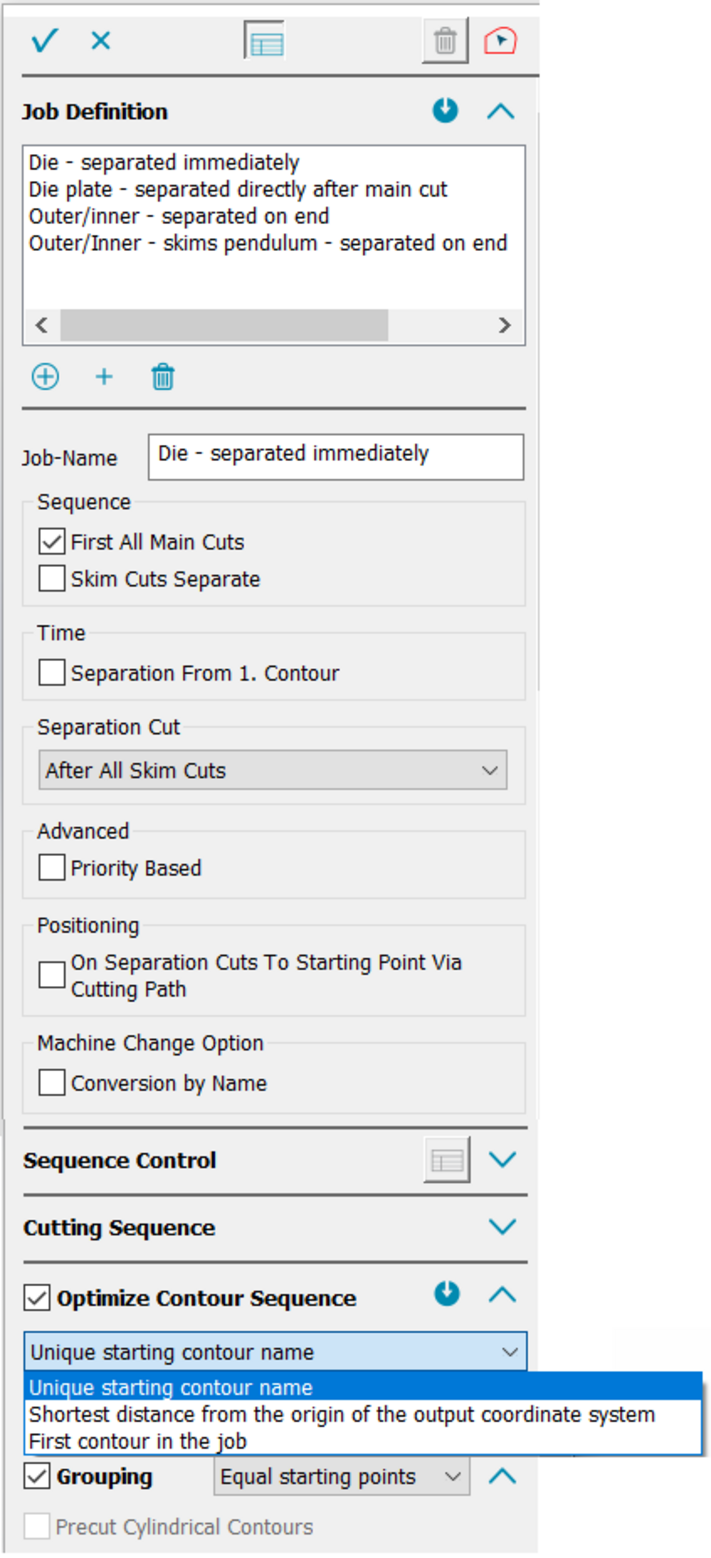

> Additional optimization when assigning jobs

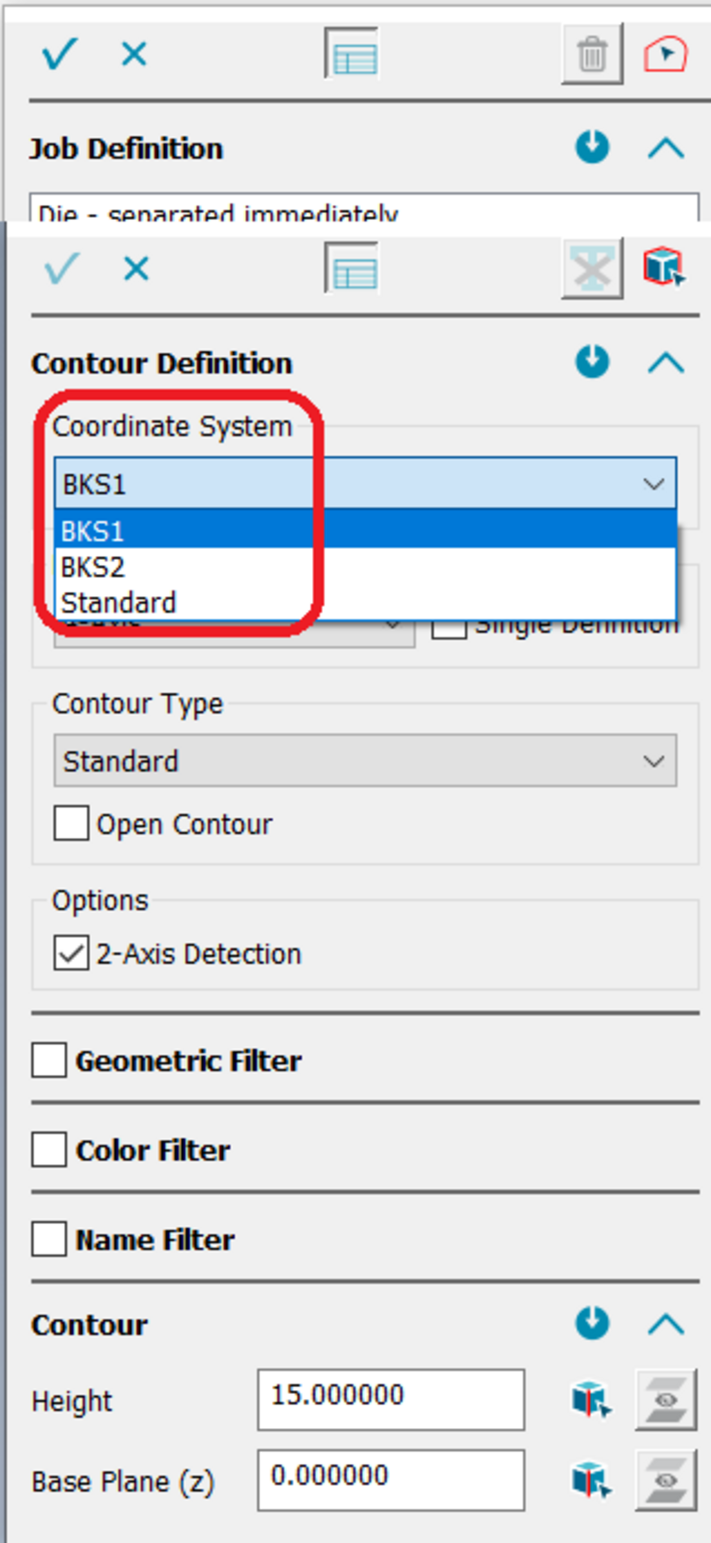

> Selection of the user coordinate system

> UNIQUA - Technology handling

> Working on the basis of the manufacturer database

> Working with manufacturer's own user technologies

- Manufacturer technology has been created on the machine and can be addressed via the technology name

- Manufacturer technology has been created on the machine and is to be read back into DCAMCUT

New options for generating contours

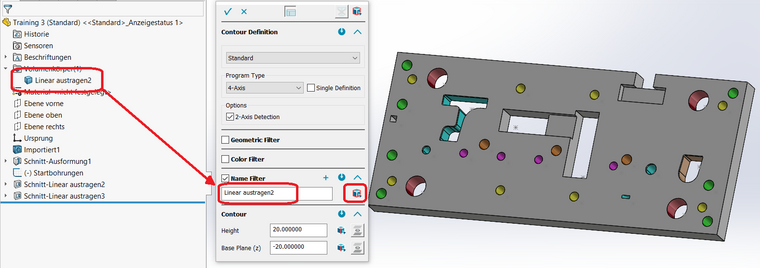

You can use the name filter to create contours based on the names of features selected in the EDMCAD Feature Browser.

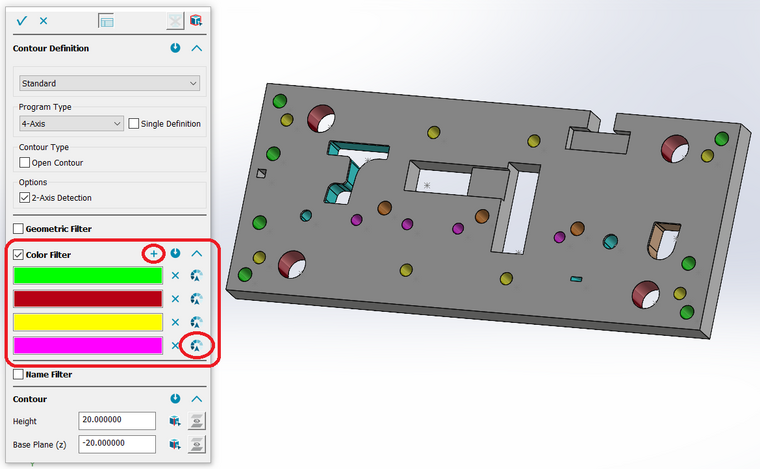

A novelty is the contour creation with several colors. This means that several open and closed contours can be created simultaneously using the color filter.

The contours created will keep their color as a DCAMCUT contour.

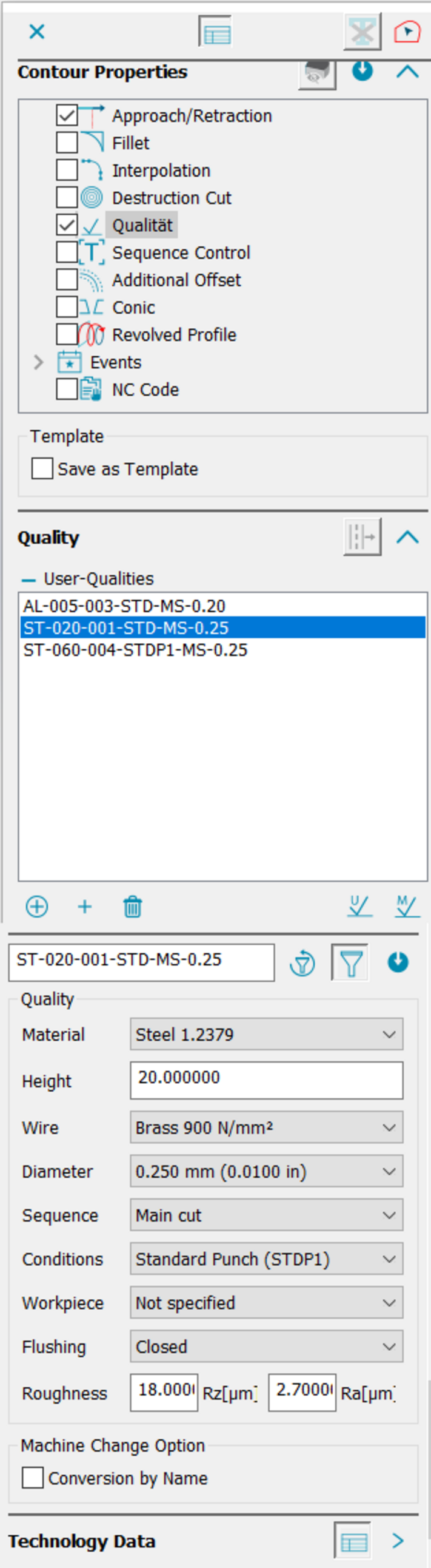

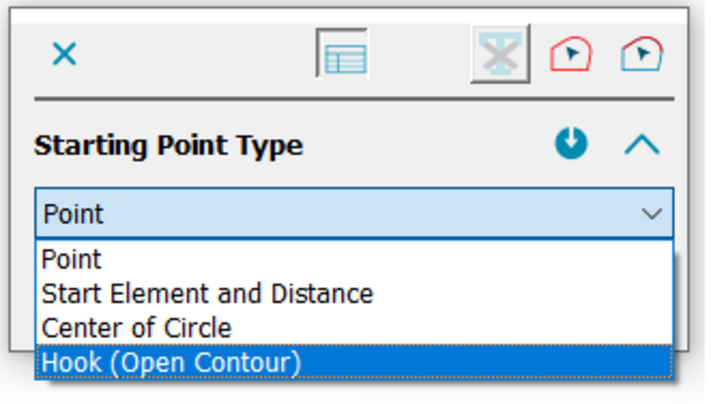

New selection filters

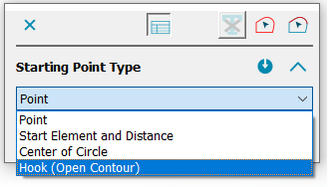

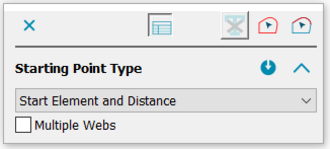

Starting points can be used on contours with the assistance of the color selection, as the color from the contour definition is transferred by the solid to the contours.

This also applies to the assignment of contour properties and job cutting sequences

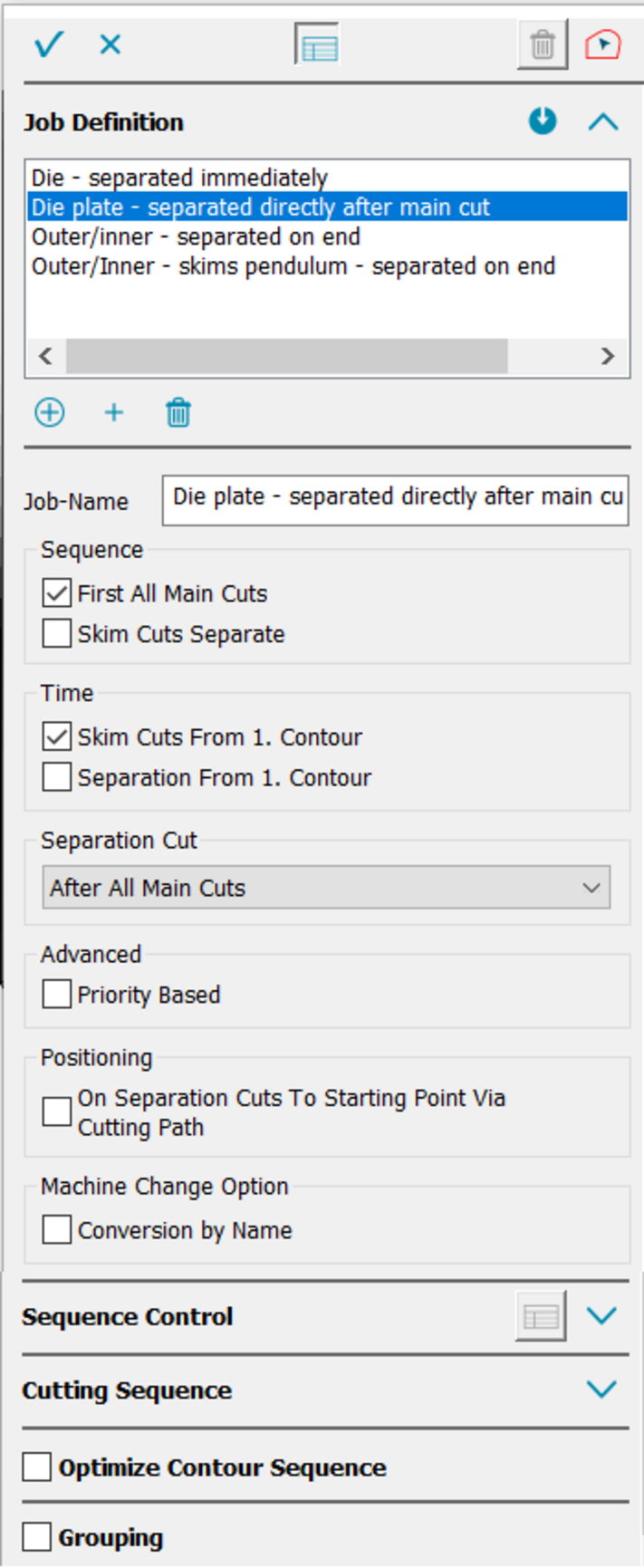

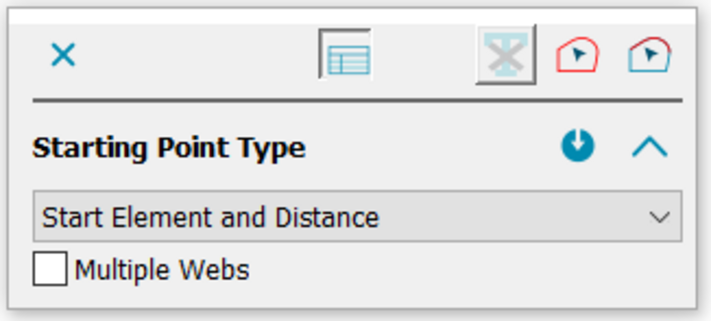

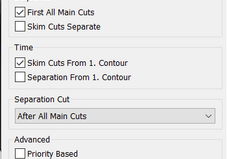

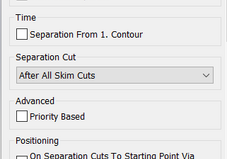

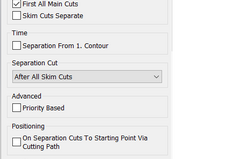

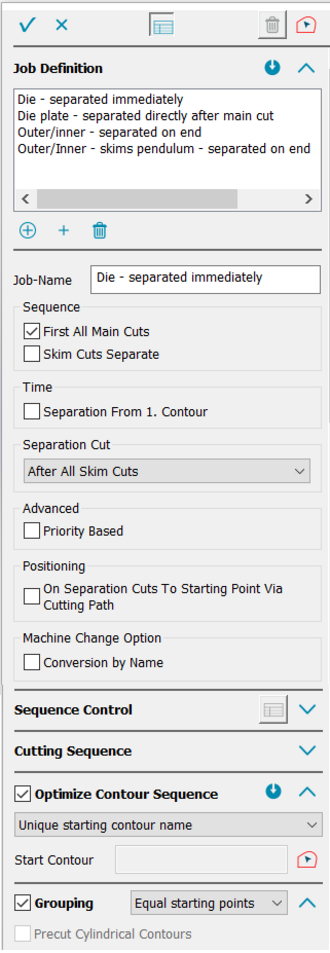

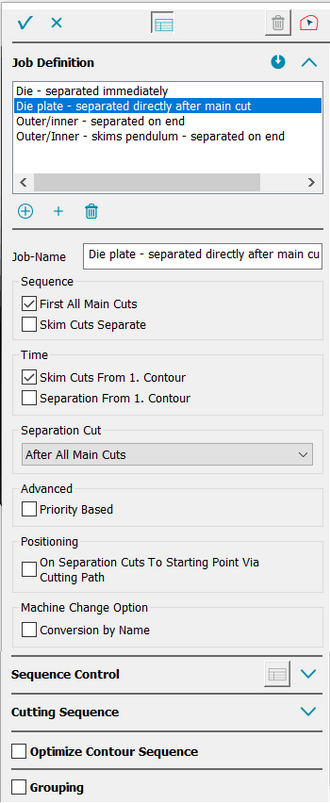

Additional optimization for job allocation

The cutting sequence of contours can be automatically optimized in the job order. Doing so generates the shortest positioning movement.

Contours with the same starting points may also be grouped to reduce positioning movements.

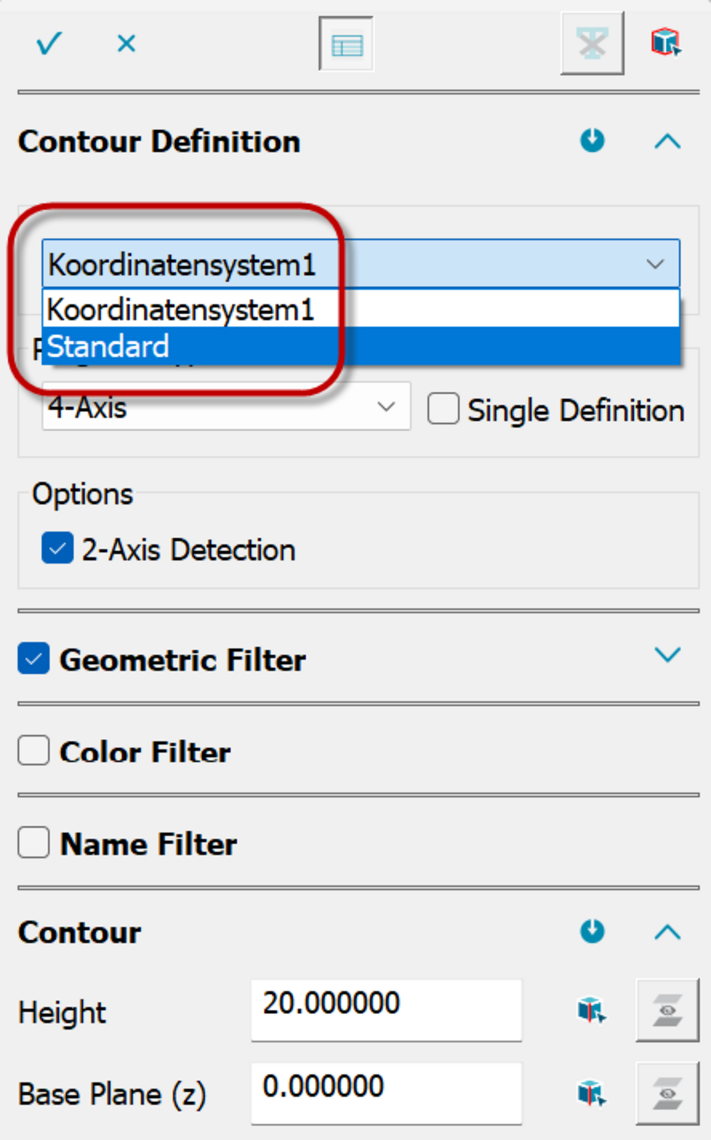

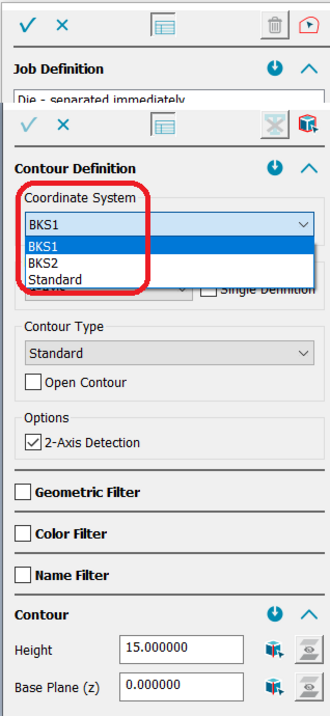

User coordinate system selection

As of this DCAMCUT version, the associated user coordinate system is directly accessible via the contour definition dialog.

UNIQUA - Technology-Handling

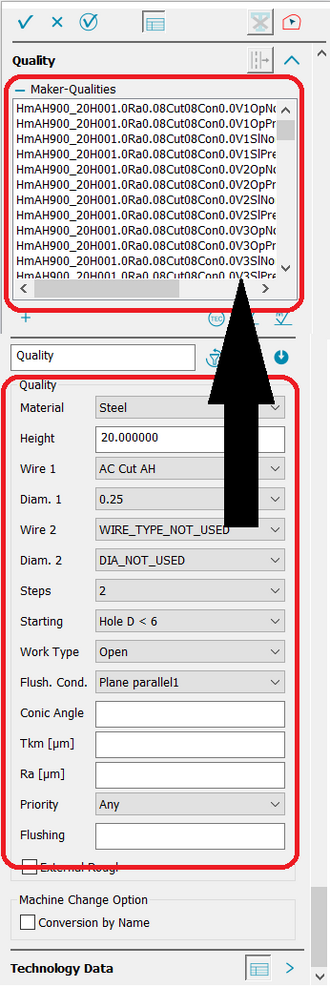

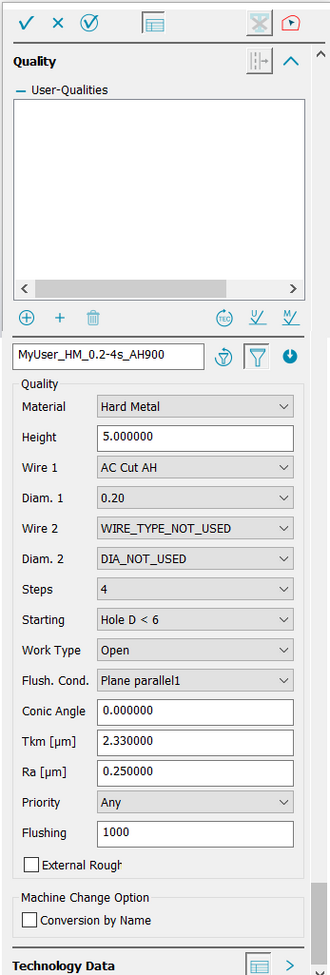

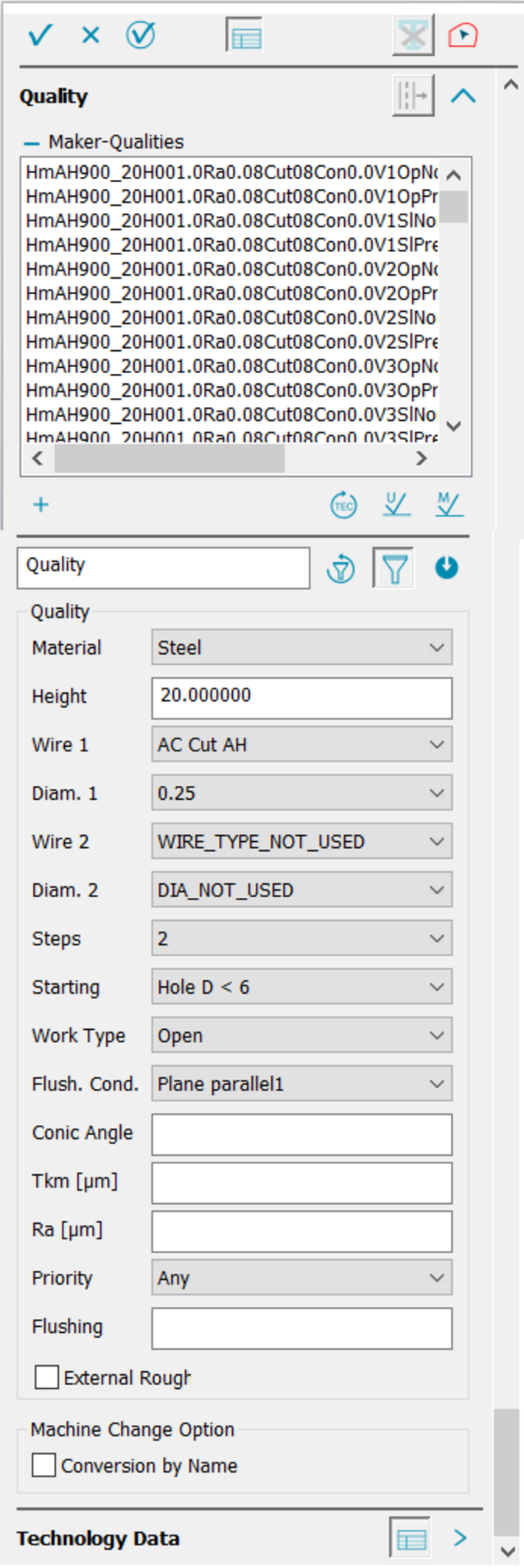

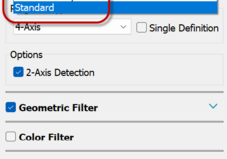

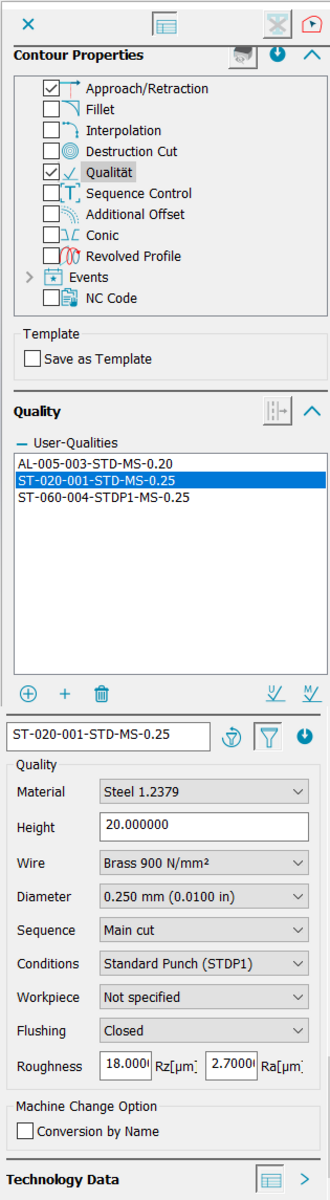

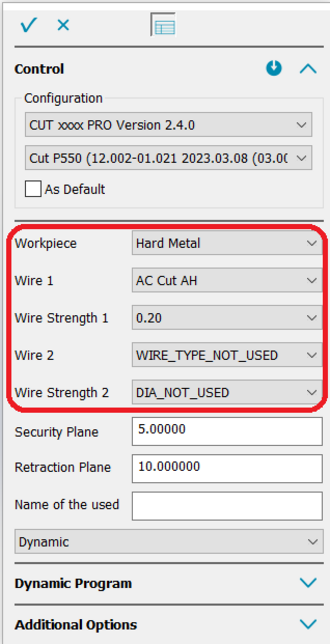

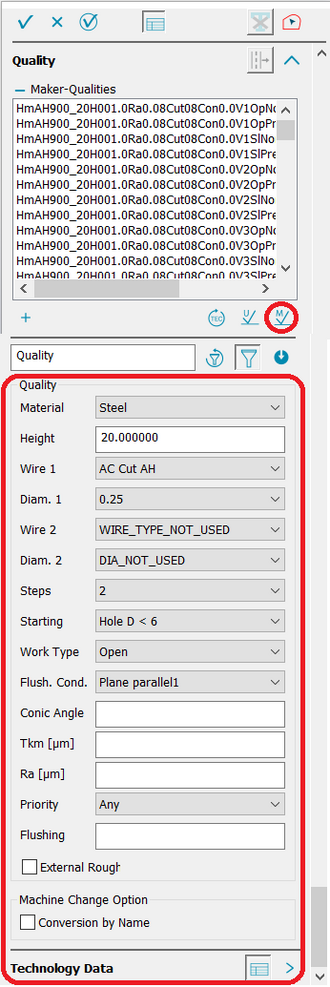

Working based on the manufacturer database

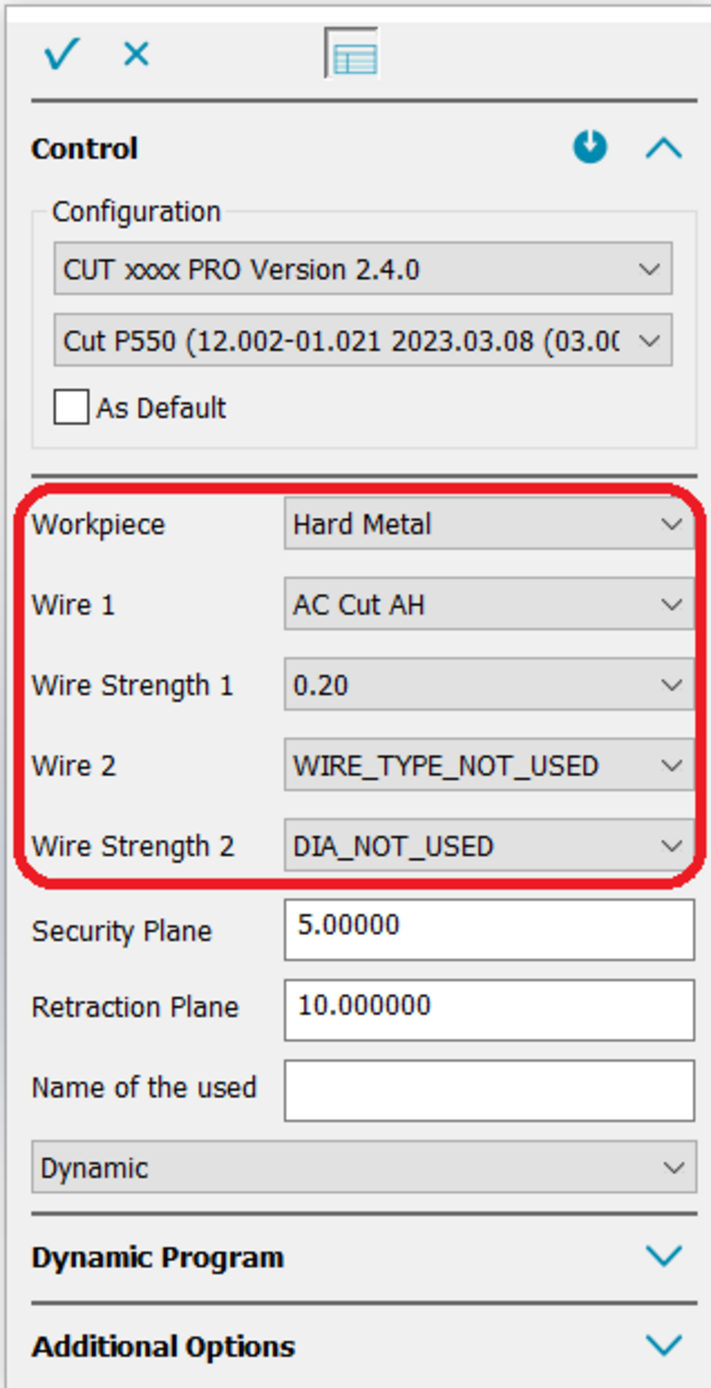

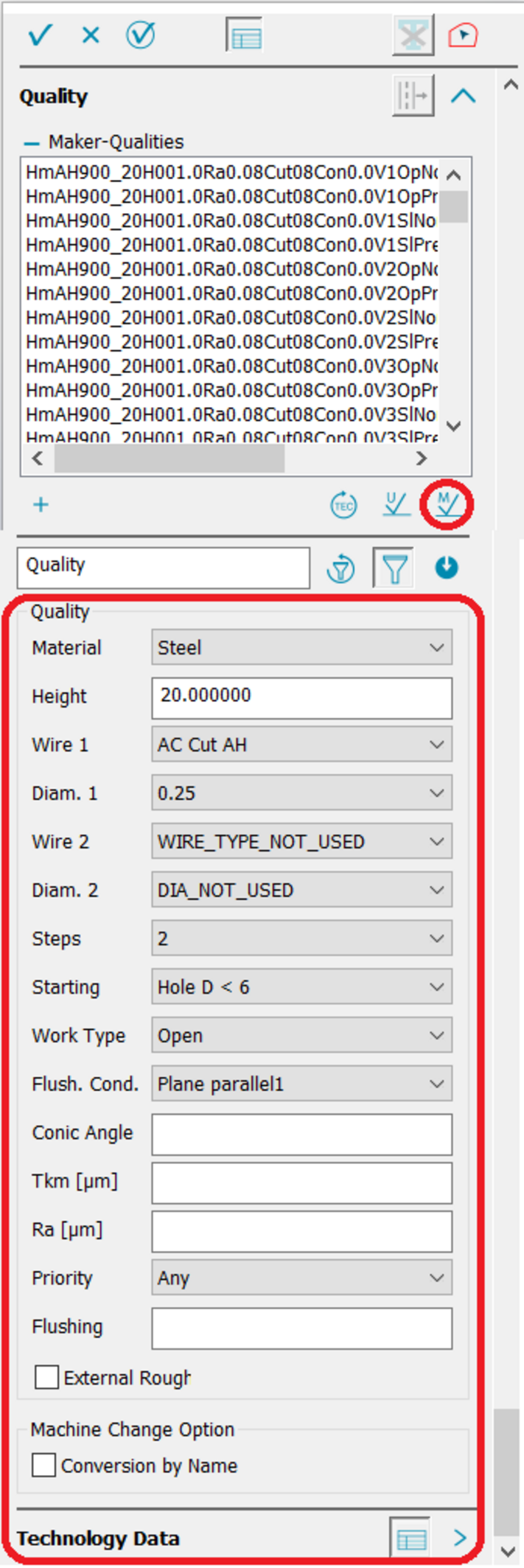

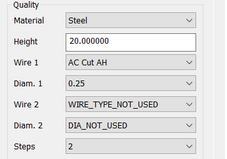

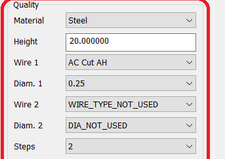

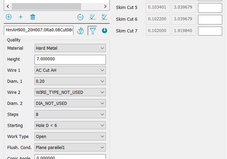

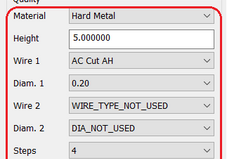

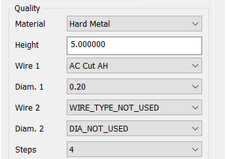

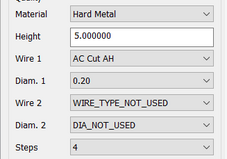

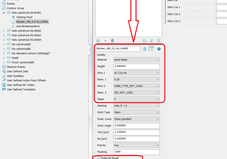

DCAMCUT uses the machine database provided by GF via an external exchange format. Due to the size of the database, it is reduced for processing in DCAMCUT based on the machining parameters specified in the machine dialog (workpiece material, erosion wire, wire thickness) and only the corresponding database is provided for quality selection and loaded as the manufacturer database.

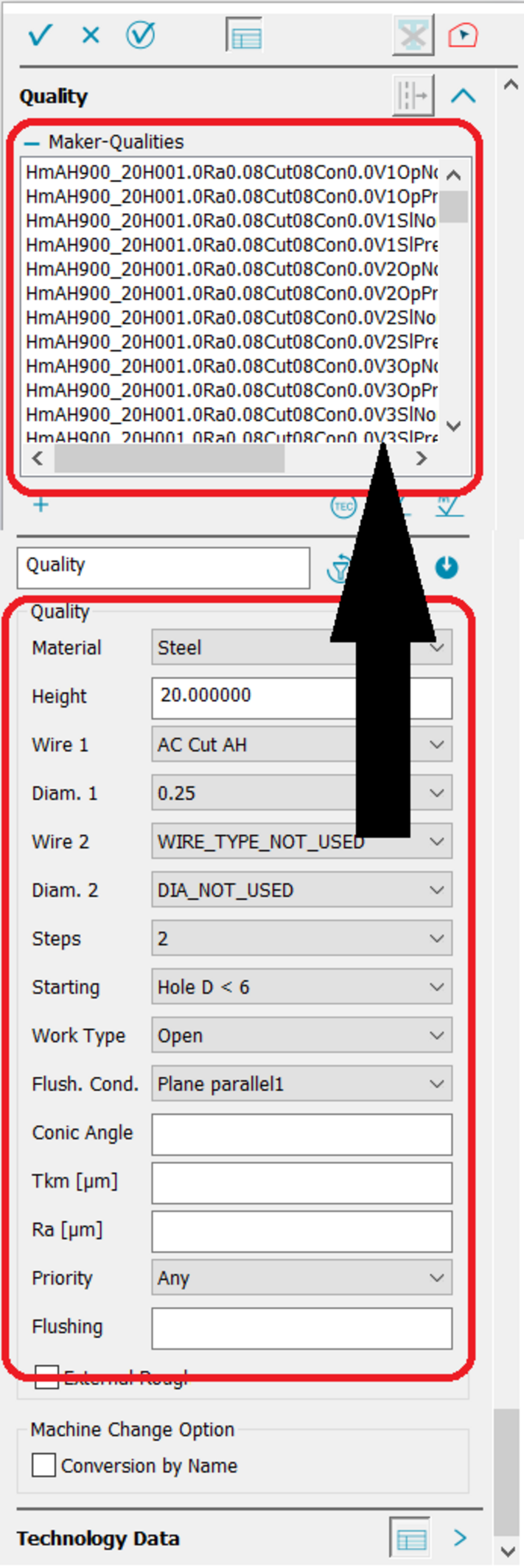

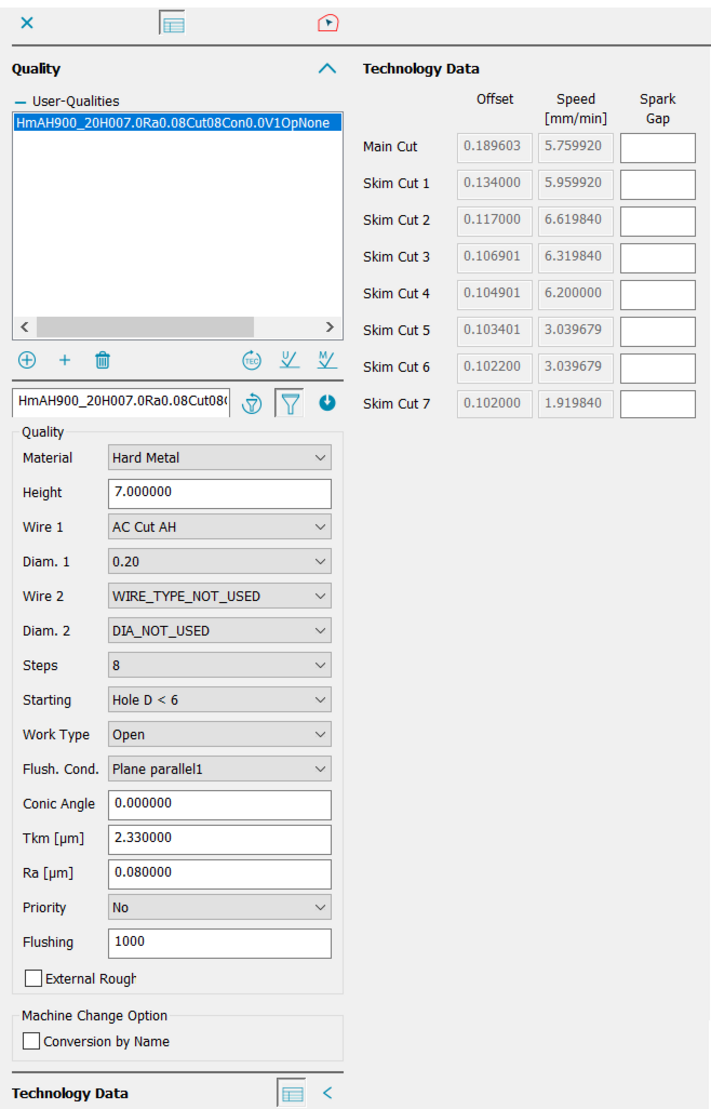

Using the filter functionality, a quality can be selected from this database and assigned to a process or the selection can be adopted as a user technology.

The basic selection without height parameters provides an overview of the technologies available as standard.

If the exact processing height is not in the machine's basic database, but is within the height range between two technologies shown in the list,

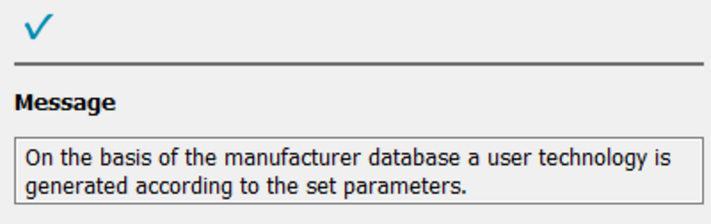

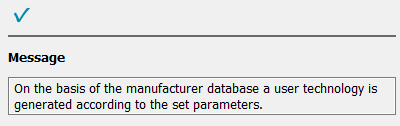

the system can generate a user technology for this intermediate height, just like on the machine. This is automatically transferred to DCAMCUT.

The calculation of the individual parameters is based on an interpolation rule provided by GF, which is identical to that used in the machine.

Example:

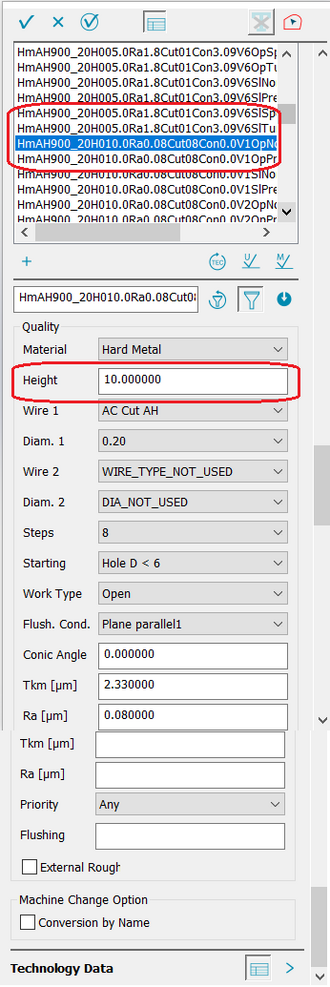

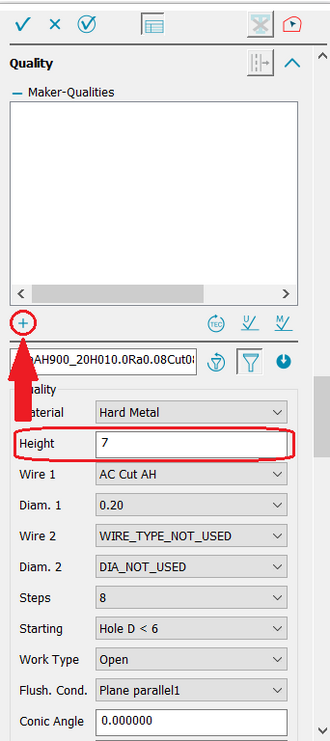

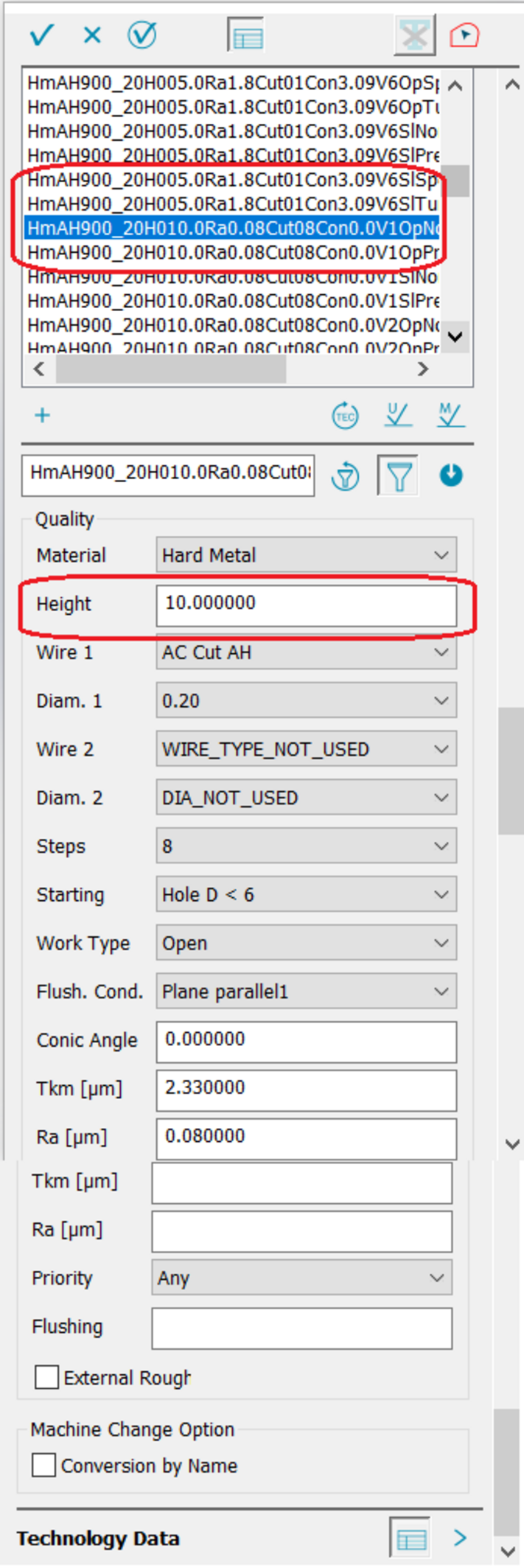

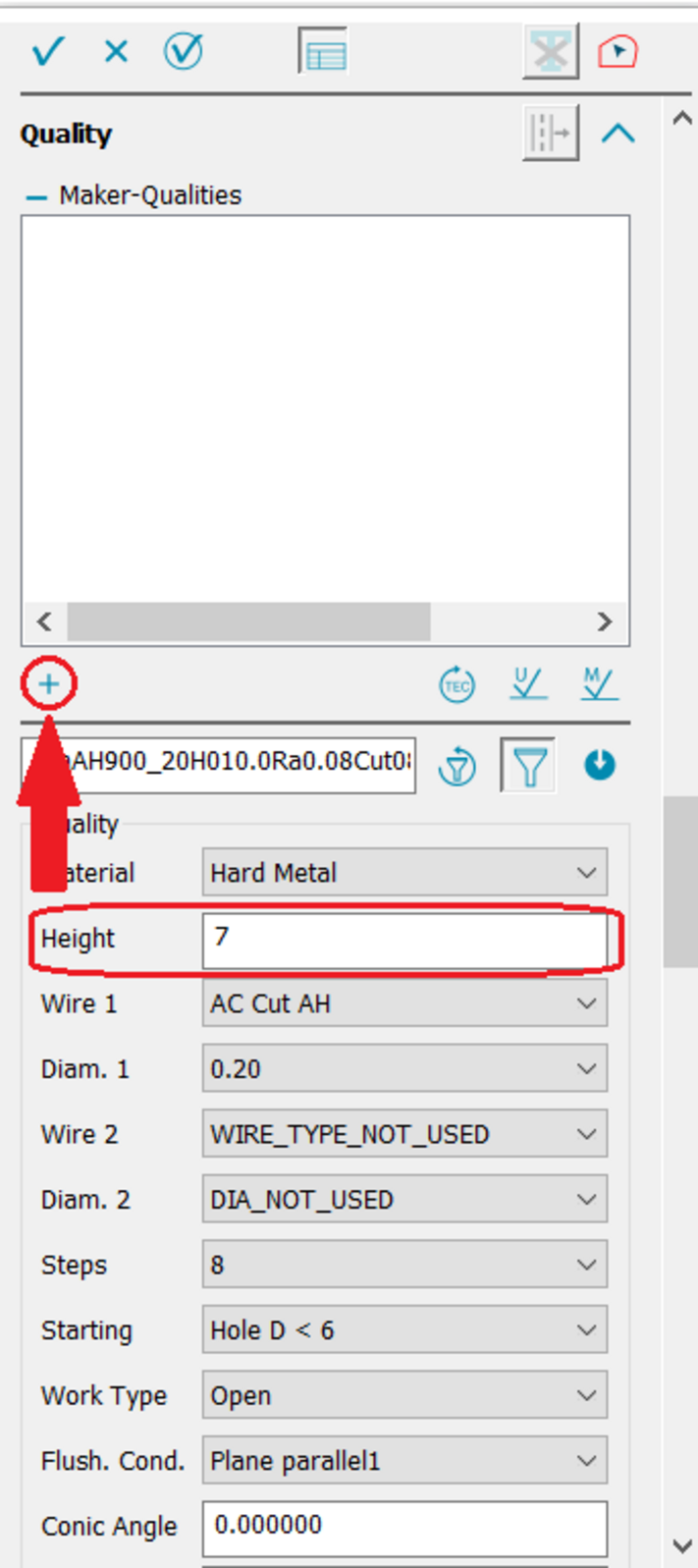

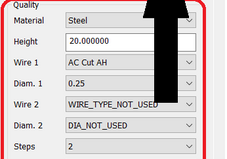

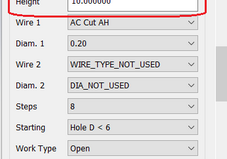

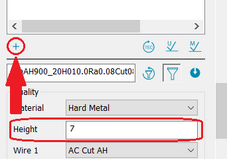

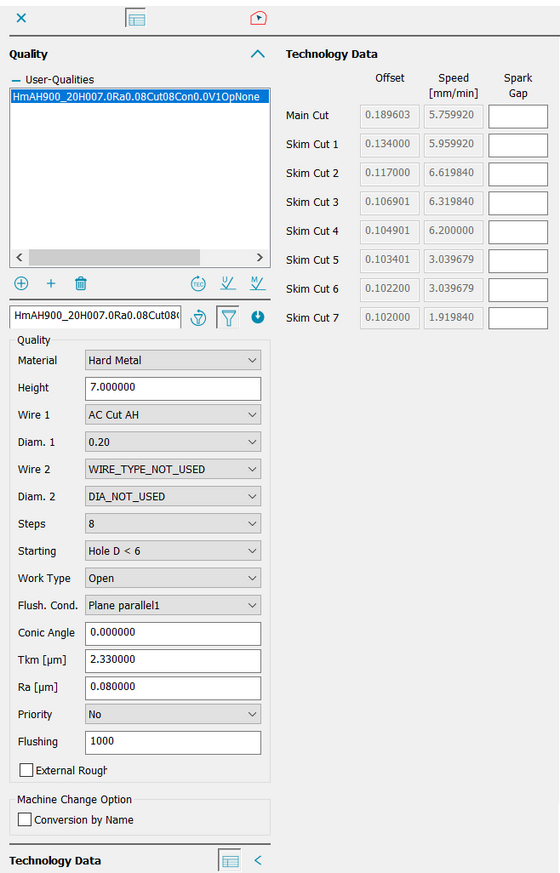

A technology with a height of 7 mm has to be generated.

In the technology list, technologies in the height range 5 and 10 mm are listed.

By entering a machining height of 7 mm and closing with

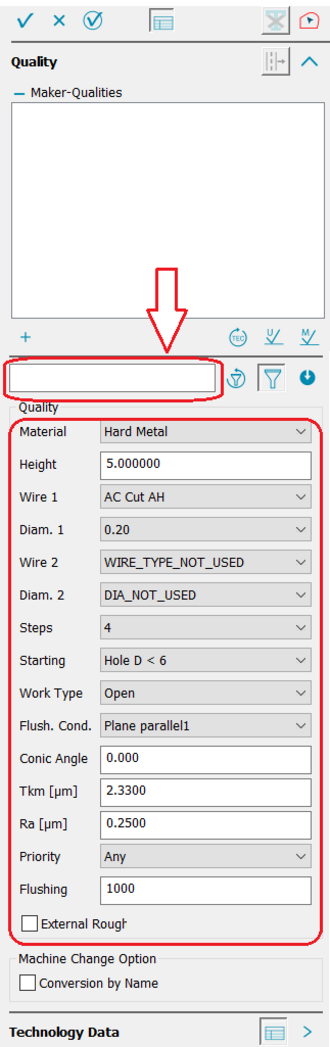

"Generate user technology", a new technology is generated on base of the basic technology.

Please select from the list of edge technologies at 7mm - 5 or 10mm, then change the height to the required processing height and transfer the technology as user technology.

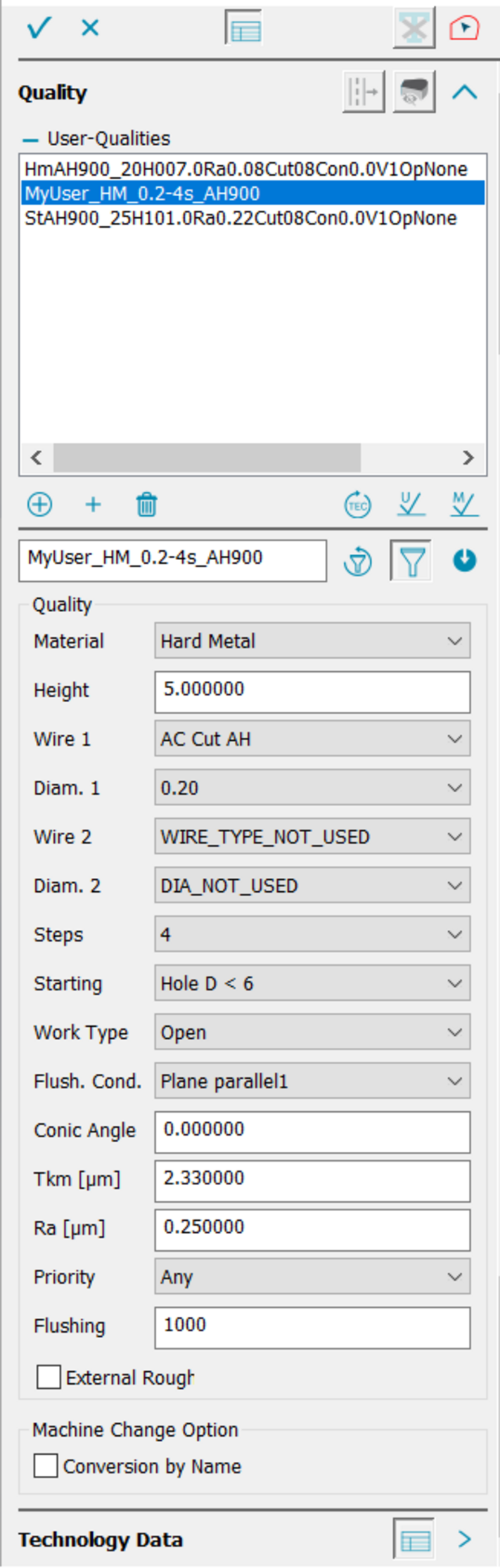

The technology created can now be used as usual.

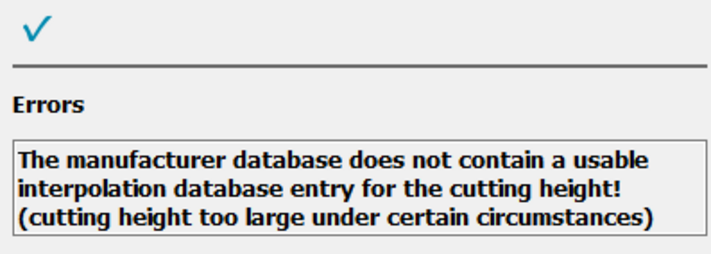

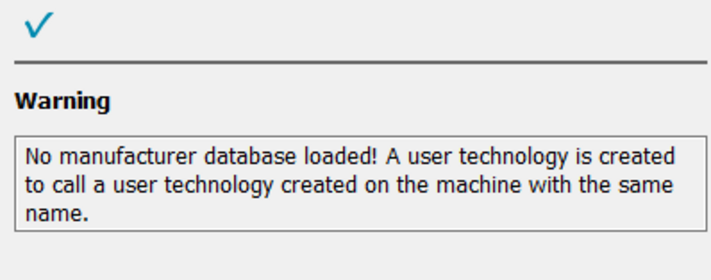

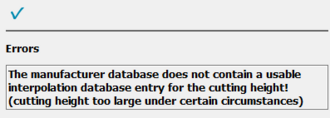

If no technology can be created on the basis of the input parameters, the following error message is generated:

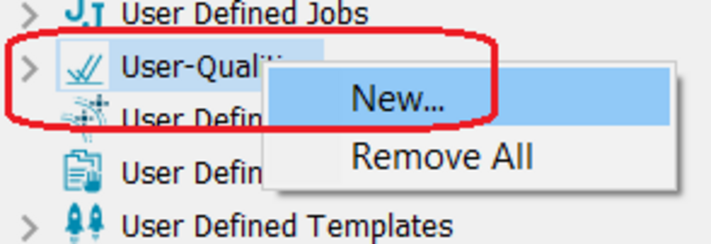

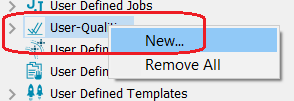

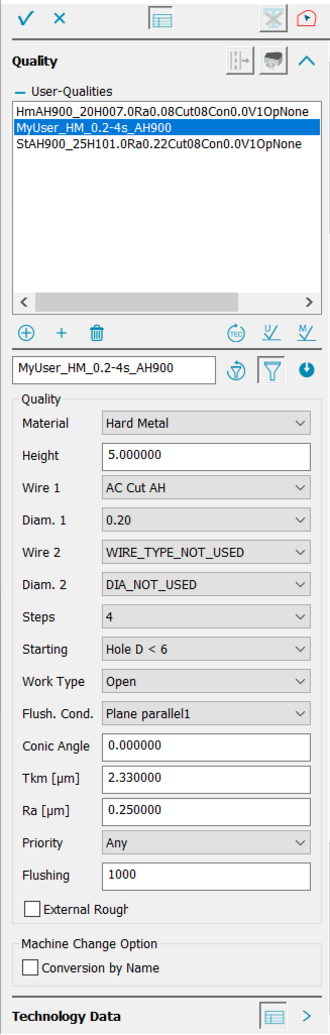

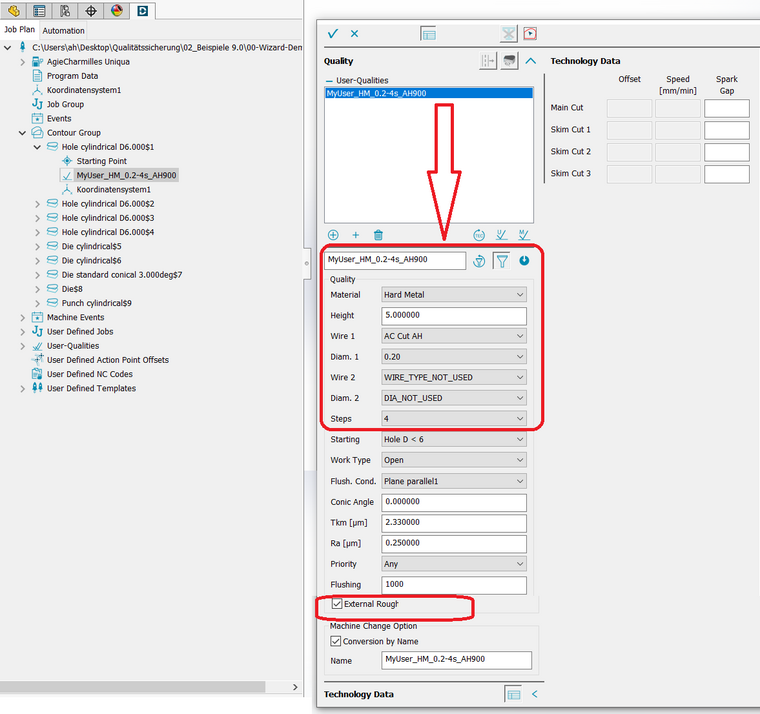

Working with the manufacturer's custom user technologies

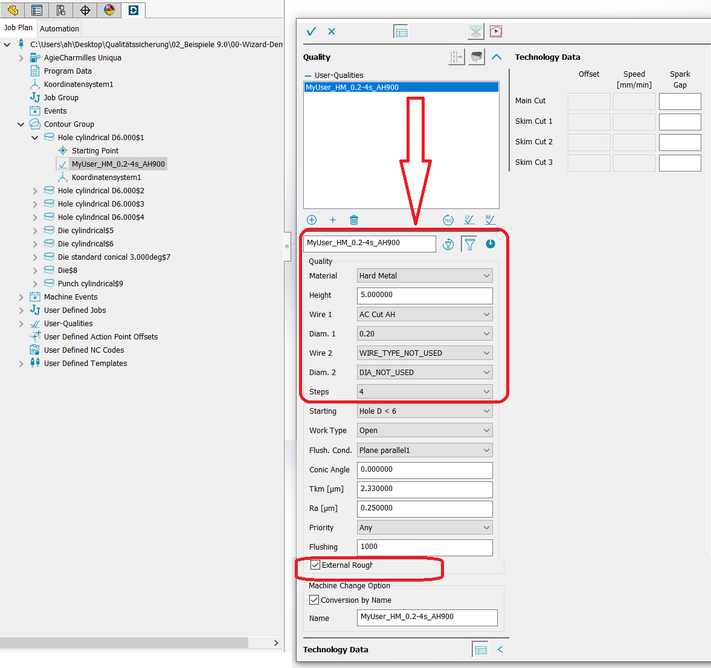

- Manufacturer technology has been created on the machine and can be accessed via the technology name.

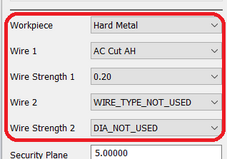

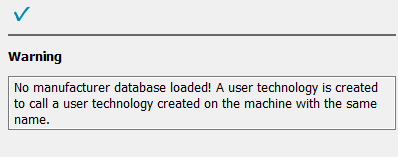

Important:

Please do not load a manufacturer database! If a manufacturer database has already been loaded, exit DCAMCUT and restart.

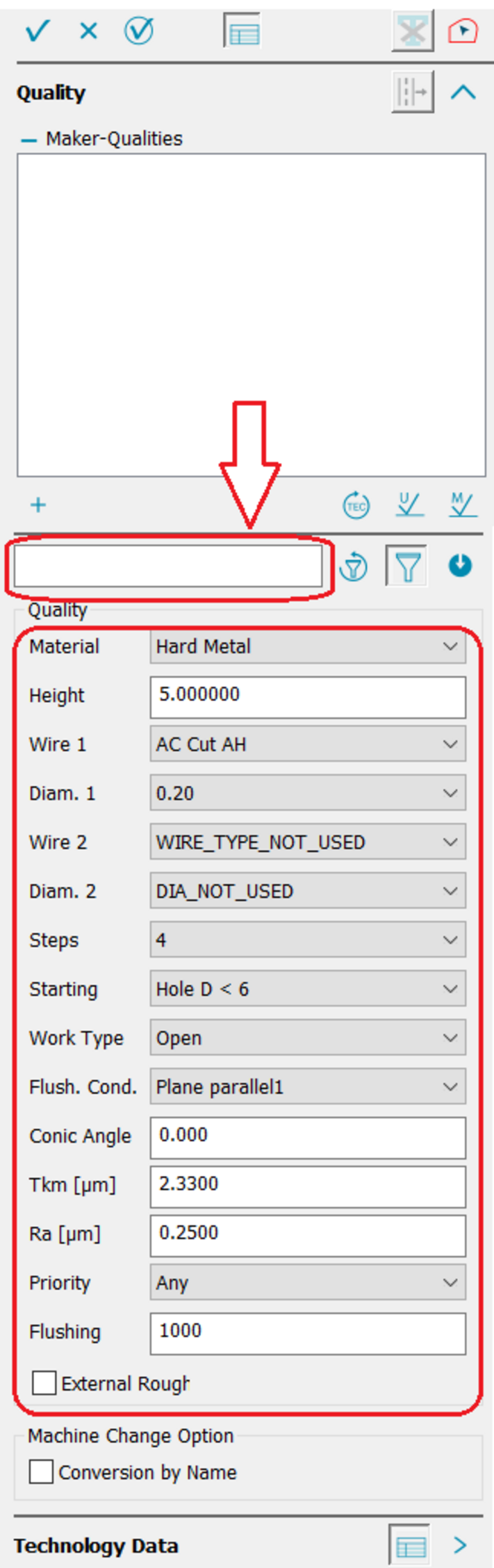

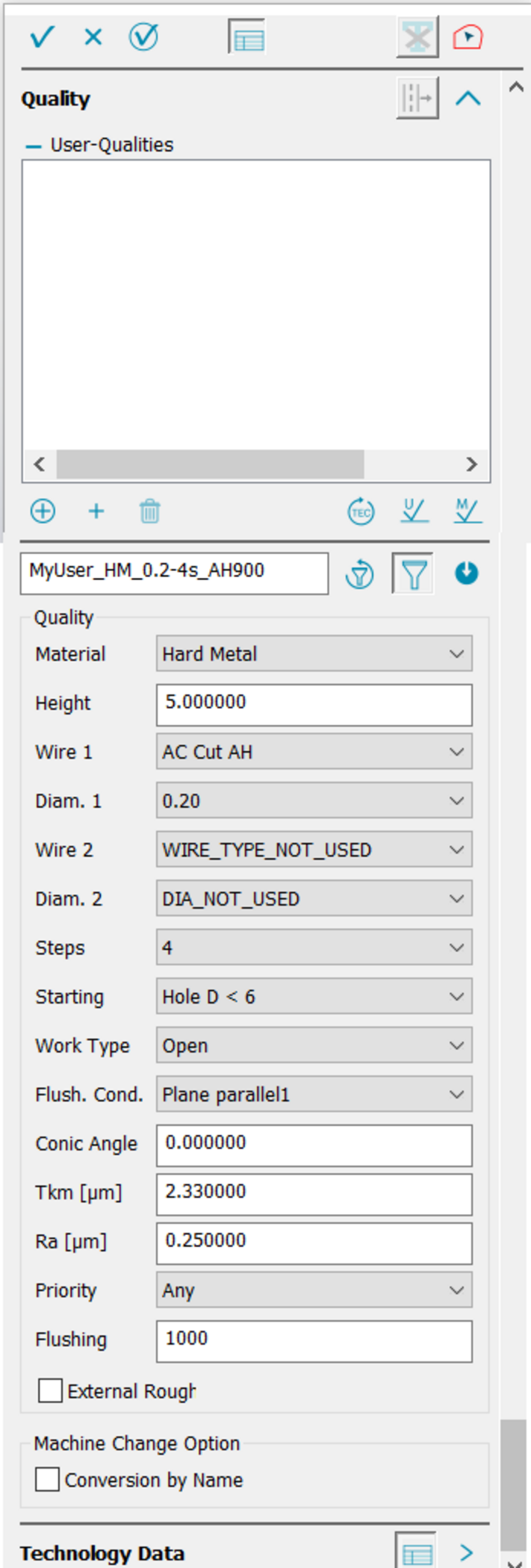

Fill the parameter set accordingly,

enter the name of the user technology,

accept as user quality..

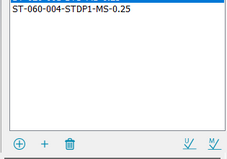

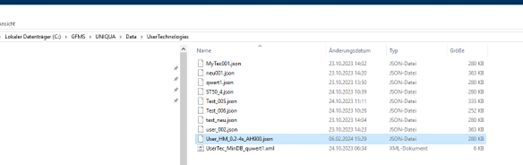

- Manufacturer technology has been generated on the machine and should be read back into DCAMCUT

The generated user technologies are generated in the following folder on the machine:

These can be exported from the machine, read into DCAM and assigned to processing:

User technologies generated via dynamic or structured programming are also read. All contained parameters and offset values are evaluated. Any parameters that are not included are marked during the transfer and must be added manually if necessary.

Overview