DressCAM X - The CAM solution

for Wire-EDM dressing on Mitsubishi Machines

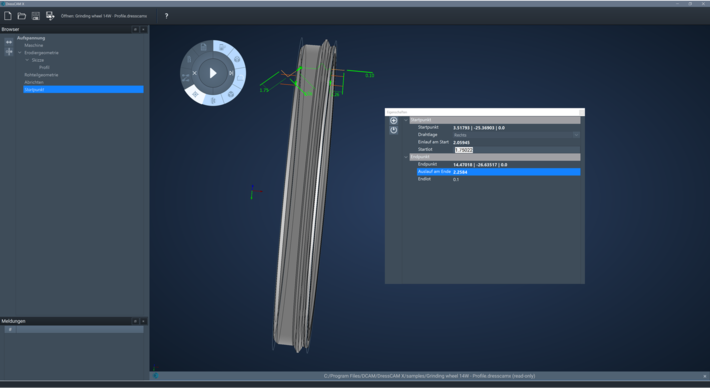

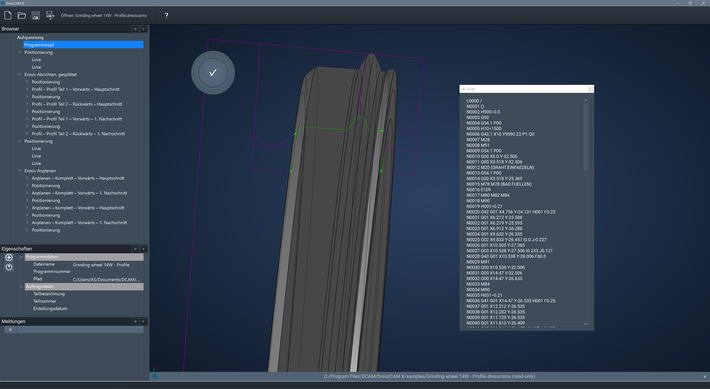

It only takes a few seconds to get from the grinding wheel profile to the technology and the respective properties, right to the final code for 100 percent machine control.

Using DressCAM X, dressing of profiled grinding wheels can be carried out easily and precisely directly on the machine control thanks to intuitive user guidance.

The process generator, the central control element in DressCAM X, guides the user automatically to the goal with just a few simple mouse clicks, even without a great deal of prior knowledge.

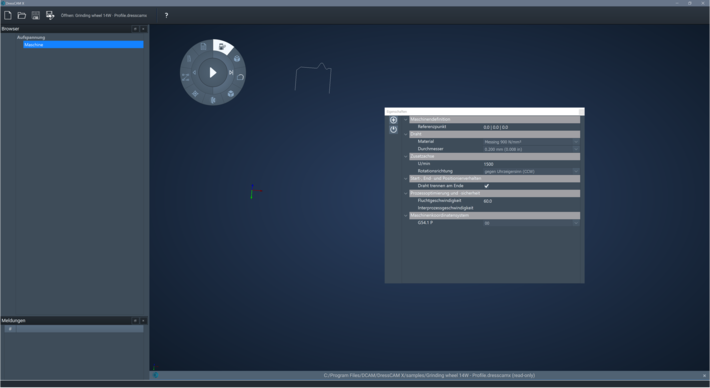

By means of intuitive and smart user guidance in the Process-Generator (top center), the program guides you click by click, automated via the program browser (top left) and the Property Grid (bottom left) to the finished processing.

Features

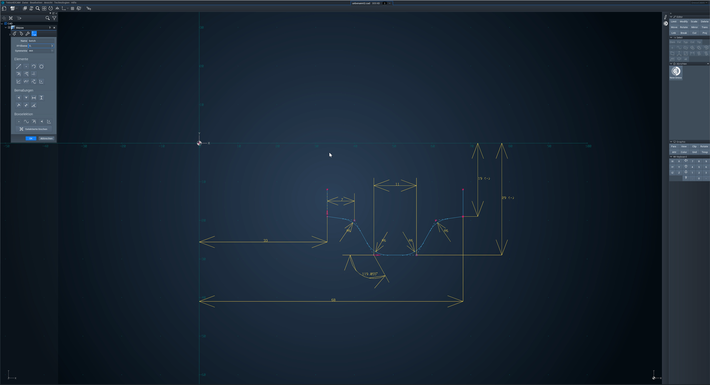

EDM geometry

From the loading of the geometry data to the NC program in just a few seconds. That's how we intended it to be.

100 percent machine control

The extension of DressCAM X with Sketcher, the integrated CAD solution allows you to correct or easily create contours.